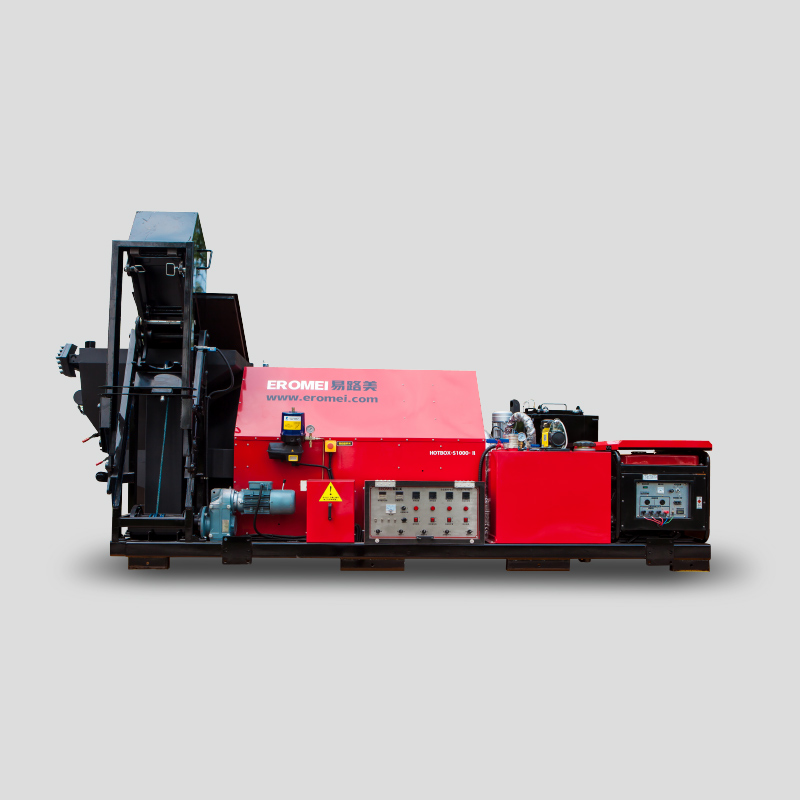

HOTBOX-S1000-II Hot-reclaimed Comprehensive Maintenance car (vehicle-mounted split-type)

Rapid heating and stirring

Asphalt Mixture Recycling

Hot Asphalt Heating and Insulation

Automatic feeding

HOTBOX-S1000-II

HOT-RECLAIMED COMPREHENSIVE MAINTENANCE CAR (VEHICLE-MOUNTED SPLIT-TYPE)

The equipment is a professional comprehensive asphalt road thermal regeneration repair equipment. It is mainly composed of chassis support system, drum material box heating system, hot asphalt heating insulation and adding system, smoke filter system, automatic feeding system, emulsified asphalt spraying system (optional), power system and electronic control system.

The equipment has many functions such as rapid heating and stirring of finished asphalt mixture, recycling of old asphalt mixture, heating and heat preservation addition of hot asphalt, spraying of emulsified asphalt (optional), etc. It can conveniently and quickly provide hot asphalt mixture for asphalt pavement disease repair. material.

Before

After

PRODUCT DESCRIPTION

• Automatic loading device

Equipped with automatic feeding device, the volume of feeding hopper is 0.1 m³, which drives the hopper to rise and unload automatically through the gearmotor, and the overall control operation is completed on the control panel to reduce the labor intensity of the construction personnel; meanwhile, the feeding hopper is equipped with inertia vibrator to assist the feeding.

• Old material regeneration and new material production

Equipped with automatic feeding device, the volume of feeding hopper is 0.1 m³, which drives the hopper to rise and unload automatically through the gearmotor, and the overall control operation is completed on the control panel to reduce the labor intensity of the construction personnel; meanwhile, the feeding hopper is equipped with inertia vibrator to assist the feeding.

• Higher heating efficiency

The drum of the equipment adopts the hot air circulation heating mode to ensure that the heating air flow can directly and effectively heat the asphalt mixture, and cooperate with the drum mixing function to achieve the uniform heating of the asphalt mixture and improve the heating efficiency. The first heating time is 20-25min, and the continuous heating time is 15-20min, hot asphalt mixture can be produced quickly in the construction site, and materials can be provided for repairing pavement diseases in time.

• Hot asphalt heating hose

It is equipped with 4.8m hot asphalt heating hose, which is used for the transportation of hot asphalt. The temperature is accurately controlled by the temperature controller to ensure that the temperature of asphalt does not decrease during the filling process and to avoid the asphalt solidification in the hose.

• Filtering and dedusting device

The equipment is equipped with a whirlwind dust removal filter system, which can filter the smoke and dust generated inside the drum and enter the drum again. This can not only prevent the dust from polluting the environment, but also avoid heat loss, reduce the heating time of the asphalt mixture, and improve the heating efficiency.

• Stable and efficient burner

Diesel burner adopts imported brand RIELLO to ensure more stable operation and higher heating efficiency.

• More accurate Intelligent multi-point temperature control

Imported Omron temperature controller can adjust the heating temperature according to the different kinds of sealant. The real- time monitoring and control of the temperature of sealant, heat transfer oil and electric heating hose in the hot melting kettle are carried out to ensure that thetemperature of sealant is within the controllable range.

• Powerful, durable and stable

The equipment uses high-performance generator set to provide power to the whole equipment (220/380V), so that the equipment has a continuous power input, strong power generator set, stable voltage and power output, while Low engine fuel consumption. The equipment has a long service life and lower cost.

• Convenient transportation

The equipment has an auxiliary loading and unloading system, which can be equipped with a hand Jack to lift the whole equipment and load it onto the transport vehicle. When it is used, it is directly placed on the chassis vehicle, when it is not used, the loading part is removed, and the chassis vehicle can be used as an independent transport vehicle.

CONSTRUCTION PROCESS

①Crush the damaged asphalt pavement

②Recycled the old material from hopper to roller heating box

③Set temperature for heating and regeneration

④Discharge and pave

⑤Compacted asphalt

⑥Patching complete

SCOPE OF APPLICATION

It can be used to repair potholes, ruts, oil bags, cracks, damaged roads around manhole covers, etc.

Sinking

Loose

Cracked

Pothole

Highways

National roads

Urban roads

Airports

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur